A solar cell, or photovoltaic cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon, solar cells are described as being photovoltaic, irrespective of whether the source is sunlight or an artificial light, a large majority of solar cells are made from silicon, but individual silicon cell is quite small, typically about 6 inches square producing only about 1 or 2 watts of power.

To boost the total power output from solar cells, they are connected together to form larger units called solar modules (panels). These modules are usually encased in glass or plastic to provide protection from the weather. Solar modules, in turn, can be connected to form larger units called solar arrays. In this way, solar systems can be built to meet almost any electric power requirement, small or large.

How Solar Cell Works?

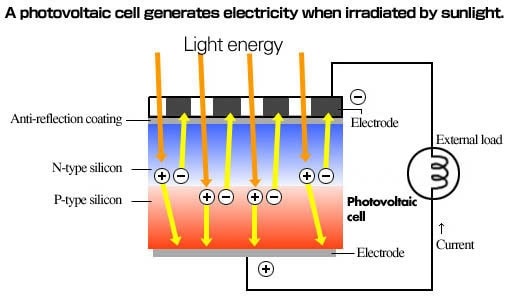

A photovoltaic cell comprises P-type and N-type semiconductors with different electrical properties, joined together. The joint between these two semiconductors is called the “P-N junction”.

Sunlight striking the photovoltaic cell and are absorbed by the cell, the energy of the absorbed light generates particles with positive or negative charge (holes and electrons), which move about or shift freely in all directions within the cell. The electrons (-) tend to collect in the N-type semiconductor, and the holes (+) in the P-type semiconductor.

Therefore, when an external load, such as an electric bulb or an electric motor, is connected between the front and back electrodes, electricity flows in the cell.

The Efficiency of Solar Cell

It was first calculated by William Shockley and Hans Queisser in 1961. A solar cell’s energy conversion efficiency is the percentage of power converted from sun-light to electrical energy under “standard test conditions” (STC).

The STC conditions approximate solar noon at the spring and autumn equinoxes in the continental United States with the surface of the solar cell aimed directly at the sun.

The modern SQ Limit calculation is a maximum efficiency of 33% for any type of single junction solar cell. The original calculation by Shockley and Queisser was 30% for a silicon solar cell.

Current solar cell production efficiencies vary by the band gap of the semiconductor material. The best modern production silicon cell efficiency is 24% at the cell level and 20% at the module level as reported by SunPower in March of, 2012.

In a laboratory, the record solar cell efficiency is held by the University Of New South Wales in Sydney, Australia at 25%. There are a number of assumptions associated with the SQ Limit that restrict its general applicability to all types of solar cells. Although there are numerous pro- grams underway to find ways around the SQ Limit, it is still applicable to 99.9% of the solar cells on the market today.

Where Does The 67% Of Energy Loss Go?

- 47% of the solar energy gets converted to heat.

- 18% of the photons pass through the solar cell.

- 02% of energy is lost from local recombination of newly created holes and electrons.

- 33% of the sun’s energy is theoretically converted to electricity.

- 100% total sun’s energy.

If the theoretical limit for silicon cells is about 30%, what happens to the other 6% that is lost from the best production cell efficiency of 24%? Some sunlight is always reflected off the surface of the cell even though the surface is usually texturized and coated with an anti-reflective coating. In addition there are some losses at the junction of the silicon cell with the electrical contacts that carry the current to the load. Finally, there are some losses due to manufacturing impurities in the silicon

Generations of Solar Cells

The First Generation: Traditional solar cells are made from silicon, are currently the most efficient solar cells available for residential use and account for around 80 percent of all the solar panelssold around the world. Generally silicon based solar cells are more efficient and longer lasting than non silicon based cells. However, they are more at risk to lose some of their efficiency at higher temperatures ( hot sunny days), than thin-film solar cells. There are three types of silicon cells used in the production of solar panels for residential use. The types are based on the type of silicon used, specifically

1. Monocrystalline Silicon: Cells Crystalline silicon PV cells are the most common solar cells used in commercially available solar panels, Crystalline silicon PV cells have laboratory energy conversion efficiencies over 25% for single-crystal cells and over 20% for multicrystalline cells. However, industrially produced solar modules currently achieve efficiencies ranging from 18% – 25% under standard test conditions.

Monocrystalline silicon PV cells are made from silicon wafers that are cut from cylindrical single-crystal silicon ingots. The rotund cells have to be cut to form nearly quadratic cells, that can be easily integrated in one module. Thus, refined silicon is wasted in the cell production process. Monocrystalline silicon shows predictable and uniform behaviour, but, due to the careful and slow manufacturing processes required, it is also the most expensive type of silicon.

2. Polycrstalline Silicon Cells: Polycrystalline or multi-crystalline silicon PV cells are made from cast square in- gots-large blocks of molten silicon, carefully cooled and solidified. They are less expensive to produce than monocrystalline silicon PV cells, but are marginally less efficient, with module conversion efficiencies between 13% and 16%

3. Multi-junction cells: 40% Multi-junction cell is not type of silicon cells but it is from the first generation cells, its efficiency up to 40 %

The Second Generation: Second-generation solar cells are usually called thin-film solar cells because when compared to crystalline silicon based cells they are made from layers of semiconductor materials only a few micrometers thick. The combination of using less material and lower cost manufacturing processes allow the manufacturers of solar panels made from this type of technology to produce and sell panels at a much lower cost, there are basically three types of solar cells that are considered in this category, amorphous silicon, and two that are made from non-silicon materials namely cadmium telluride (CdTe), and copper indium gallium selenium (CIGS).

The Third Generation: Currently there is a lot of solar research going on in what is being referred to in the industry as Third-generation solar cells. In fact according to the number of patents filed in the United States – solar research ranks second only to research in the area of fuel cells.

This new generation of solar cells are being made from variety of new materials besides silicon, including nanotubes, silicon wires, solar inks using conventional printing press technologies, organic dyes, and conductive plastics. The goal of course is to improve on the solar cells already commercially available by making solar energy more efficient over a wider band of solar energy (e.g., including infrared ), less expensive so it can be used by more and more people, and to develop more and different uses. Currently, most of the work on third generation solar cells is being done in the laboratory, and being developed by new companies.

Solar Tracking PV Systems

To make solar energy more viable, the efficiency of solar array systems must be maximized and reduce cost, there are feasible ways to maximize efficiency of photovoltaic systems with a lower cost unlike cell development during the third generations, examples of this tracking, concentration, hybrid, and three-dimensional shape.

The tracking system is a system for orienting solar photovoltaic modules to the vertical sun and generates more electricity than their stationary counterparts due to increased direct exposure to solar rays. This increase can be as much as 10 to 25% depending on the geographic location of the tracking system.

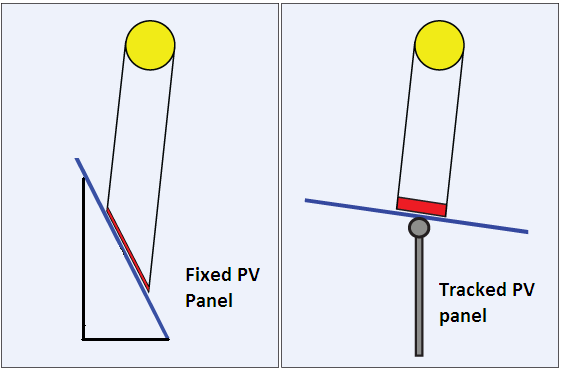

In the figure below, the panel on the left is mounted at a fixed angle and the suns rays fall at an angle thereby the intensity of light is spread out over a larger area thus producing less power.

In the next image, the PV panel is mounted on AMEC Dual Axis Solar Tracker, which keeps the panels facing the sun for the most part of the day. The sunlight strikes the panels with greater intensity thereby generating maximum energy of the PV system continuously throughout the day.

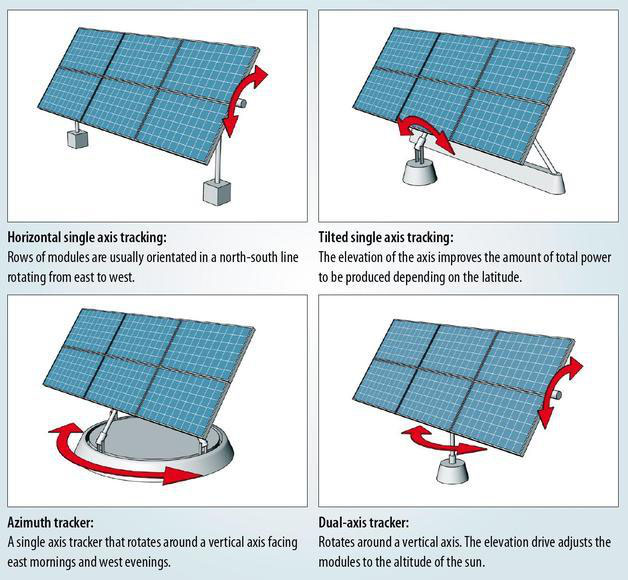

There are many different kinds of solar trackers, such as single-axis and dual-axis trackers, all of which can be the perfect fit for a unique jobsite, installation size, local weather, degree of latitude and electrical requirements are all important considerations that can influence the type of solar tracker best suited for a specific solar installation.

A Single axis solar tracker doing its best to follow the sun rotating on a single axis, because the apparent movement of the sun is due to the Earth rotating on its polar axis. In theory only one axis is required to match to movement of the sun.

In practice, in order to easily adjust for both different latitudes and for the changing declination of the sun (higher in summer, lower in winter), a design compromise is made to integrate the tilt of the modules with the tilt of the axle. This design yields a few percent in performance, but offers the benefits of good performance, simplicity and lower maintenance.

Dual axis solar trackers can come in several different configurations, but typically use a combination of azimuth/elevation axes. By design, these type of trackers have a very wide range of motion and can gain a few percent in performance over single-axis type trackers. The drawback is the complexity of the tracking mechanism (motors, controllers, sensors, gears, bearings), maintenance and cost, but advancements in technology and reliability in electronics and mechanics have drastically reduced long-term maintenance concerns for tracking systems.

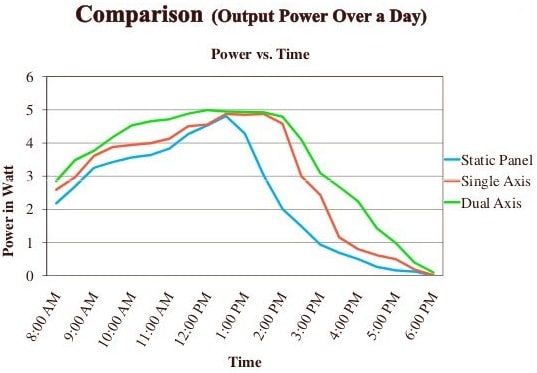

The comparison table shows the efficiency of electricity production throughout the day for each of the

- Static solar panel

- Solar trackerpanel on Single axis

- Solar trackerpanel on dual axis

Related Posts

- Solar Energy Systems

- Solar Cell | Photovoltaic Cell

- Solar Concentrator PV Systems

- 3D Solar Cells

- 3D Solar Cell Systems

- Electrical Specifications of PV Modules

- Standard Test Conditions for PV Modules

- PV Arry Charge Controllers

- Sizing a Grid-Direct PV System

- Sizing a Battery-Based PV System

- Site Survey for PV Installation

- Understanding Solar Radiation for PV Installlation

- Concentrating Solar Collectors

- Solar Energy Systems

- Solar Panel Working Principle